Our Services

and customer centric business models to create

new opportunities for enterprises.

Our Services

A Global Consulting & System Integrator, specialized in

Dassault Systèmes technologies for 10 years.

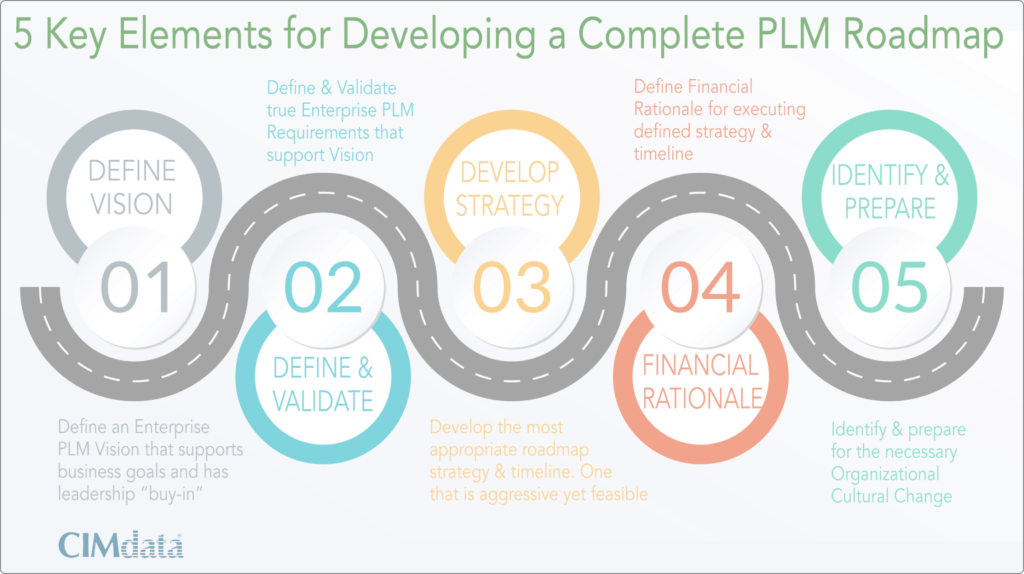

Product Lifecycle Management

PLM Consulting

BWC’s business-driven approach defines business objectives, works with customer to define PLM blueprint based on specific business requirements.

Implementation

BWC implementation methodologies focus on leveraging PLM capabilities, improving business processes while keeping customization to minimum.

Upgrade and Support

BWC enables customers to take advantage of latest features and technology of 3DEXPERIENCE by providing an upgrade to latest version, In addition, we improve the user experience by adding comprehensive support information, helping our customers stay ahead of innovation while receiving unmatched service.

Training

We provide Corporate PLM Training to suit specific needs of organizations. We also provide End User and Technical Training.

PLM Audit and Improvement

At BWC, we assess current implementation gaps with respect to the user’s expectations, identify the issues related to PLM implementation

Customization and Migration

BWC's adept team leverages extensive experience in data migration, employing proven methodologies to seamlessly transition from legacy systems to the latest versions. Our expertise extends to merging and customizing content for a cohesive and efficient migration process

Data Analytics

Predictive Maintenance

Based on rich Industry experience and expertise of Data Science, developed customer specific model and algorithms predict breakdown or maintenance.

Cognitive Document Processing

Smart document processing solution using supervised and deep learning to convert from unstructured to structure data.

Setup & Migration to Big Data

Setup and migrate application to Hadoop Stack. Implement ML algorithm to predict failures, automated user alerts.

Sentiment & Aspect Analysis

BWC has developed a unique ML based solution provides specific actionable to organizations to improve products or services based on customer feedback.

Knowledge-graph Creation

Data processed using a ML model to be presented in knowledge graph. BWC team can generate the same with combination of business and technology experience.

Auto Generation of RFQ for Suppliers

BWC has ML based cognitive document processing ML model when trained on history documents, auto generates RFQ and then integrated to PLM for further processing.

Let’s meet to know more

Connect and Meet us to discuss the roadmap for your Products, Services, Processes, and enlighten the pathway to simplicity.

Strategy, Design,

Planning

Innovation-led

best practices

Secure multi-platform /

location Product Data

Expertise with a

Competitive edge

Business value

& Growth oriented

Compliant

& Comprehensive

Our intelligent perspectives

- Jan 2023

- Jan 2022

- Jan 2022

- Feb 2021

- May 2020

- May 2020